Considerations For Pump Selection

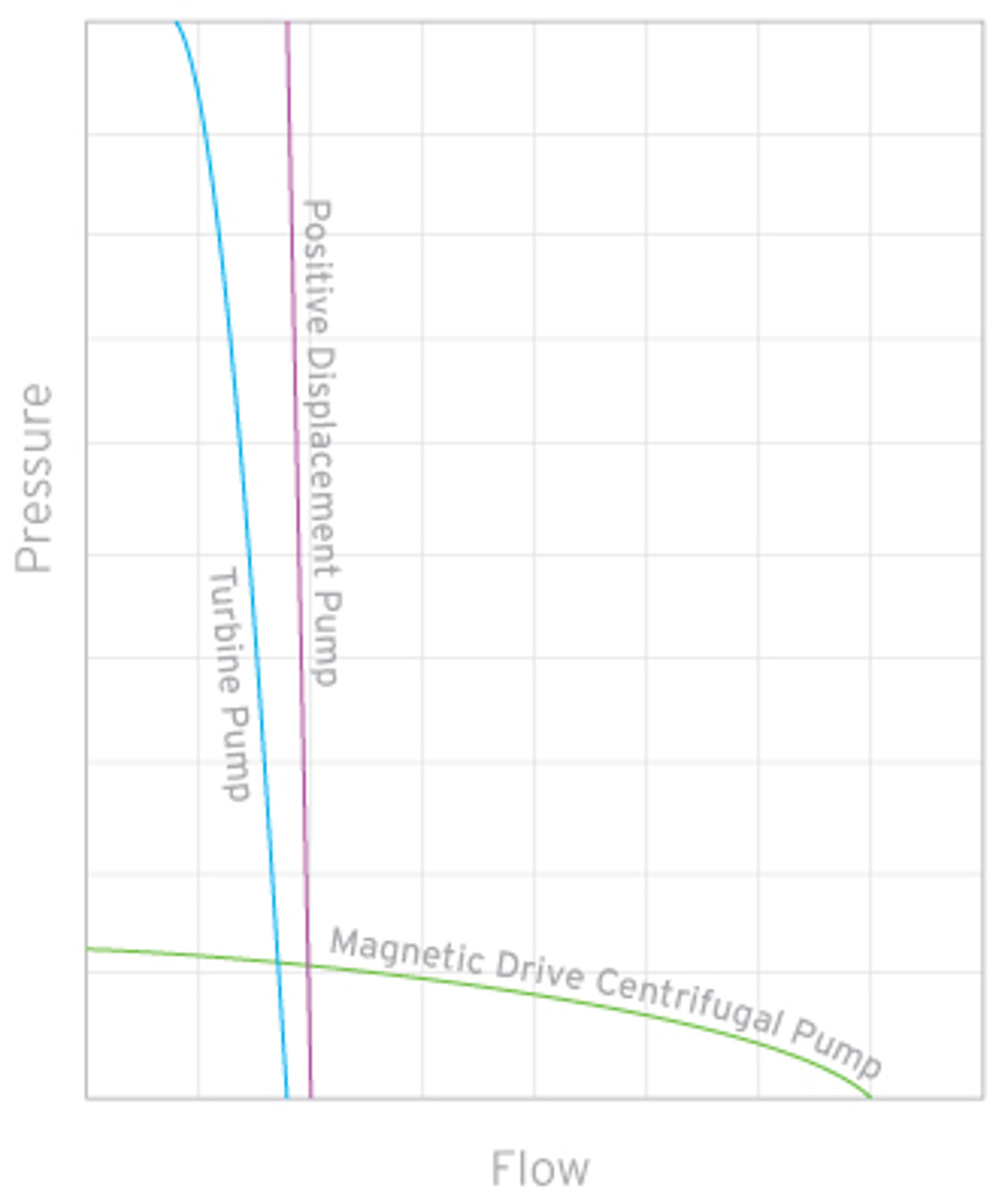

Provide moderate flow and moderate pressures (20-90 psi, 1.4-6.9 bar.) which makes them well suited to applications that require higher pressure or experience a higher system pressure drop, such as long tubing runs or pumping vertically. A robust design makes turbine pumps very reliable and forgiving to impurities in the fluid stream. Bronze turbine pumps are standard; stainless steel pumps are available.

Have performance characteristics similar to turbine pumps and are suitable for high viscosity fluids, or pumping higher or further from the cooling product and the application. They produce moderate flow at high pressure; up to 100 psi (6.9 bar). Brass positive displacement pumps are standard; stainless steel positive displacement pumps are available.

Offer higher relative flow rates at lower pressures and are suitable for applications that are in close proximity to the chiller or require lower pressure, such as glass condensers. Centrifugal pumps are very quiet and require little maintenance, but they are more sensitive to pressure drops. Chillers with this pump option that are attached to a device with a solenoid valve coolant shut-off require the external bypass accessory.